- Home

- Contact Us

- VFD Accessories

- Braking Resistor

- TBRW Series Wire Wound Braking Resistor for VFD

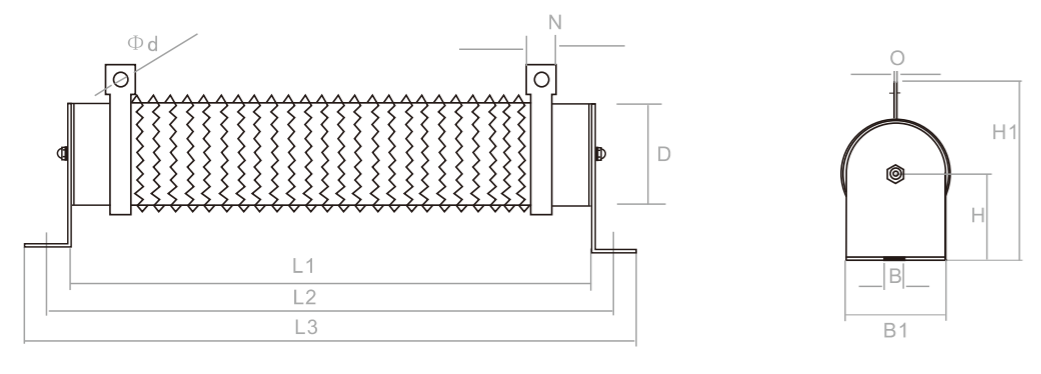

TBRW Series Wire Wound Braking Resistor for VFD

The purpose of a dynamic braking resistor is to slow down or to quickly stop a motor by draining excess voltage and keeping it within safe tolerances. Our rheostatic resistors dissipate the excess voltage as heat.

Category: Braking Resistor

- General Details

- Technical Info

- Comments

General Details

Applications:

Elevator, port machinery, rolling mills, hoist the generator, inverter and other brake and load

Use of the environment:

Rated temperature (+70 ℃); use with the temperature range (-55 ℃ ~ +375 ℃)

Structure:

rated power temperature (+70 ℃); use with the temperature range (-55 ℃ ~ +375 ℃)

Applicable standards: GB/T5729-2003 GB5732-85

| The main test items, test methods and performance requirements | ||

| Test item | Performance requirements | Test methods |

| Temperature coefficient of resistance | ≤±250(×10-6/℃) | -55℃/+20℃,20℃/+125℃ |

| Terminal Strength | R≤±(1%R+0.05Ω) | Pull 20 |

| Dielectric | No breakdown or flashover | 2500V DC,1min |

| Weldability | Solder to flow freely and with terminals infiltration | 235±5℃ 2±0.5s |

| Resistance to soldering heat | ΔR≤±(1%R+0.05Ω) | 260±5℃ 10±1s |

| Short-time overloa | ΔR≤±(2%R+0.05Ω) | 10 times the rated power, 5s |

| Rapid changes in temperature | ΔR≤±(1%R+0.05Ω) | -55 ℃ / +125 ℃ 5 cycles |

| Vibration | ΔR≤±(1%R+0.05Ω) | 10~500Hz 98m/s2 |

| Long-term load | ΔR≤±(2%R+0.05Ω) | +70±2℃ VR 1000h |

| Non-flammable | Not burning | 1 to 6 times the rated power for 5 minutes |

| Surface temperature rise | ≤350℃ | The rated power |

| Insulation resistance value | 1000MΩ | 1000V DC |

Technical Info

| d Power(W) | Resistance Range(Ω) | Outside the type size(mm) | Resistance Tolerance(%) | Temperature coefficient | ||||||||

| D±1 | L1±3 | L2±3 | h±3 | H±3 | N±1 | Ф±1 | q±1 | Q±1 | ||||

| 15W | 0.12Ω~15KΩ | 16 | 50 | 68 | 20 | 40 | 6 | 3 | 4.5 | 15 | ±5% | ±250ppm |

| 20W | 0.12Ω~20KΩ | 20 | 52 | 78 | 26 | 52 | 6 | 3 | 5 | 20 | ||

| 30W | 0.12Ω~25KΩ | 20 | 75 | 100 | 26 | 52 | 6 | 3 | 5 | 20 | ||

| 40W | 0.12Ω~30KΩ | 20 | 75 | 100 | 26 | 52 | 6 | 3 | 5 | 20 | ||

| 50W | 0.3Ω~30KΩ | 28 | 90 | 100 | 26 | 52 | 9 | 3 | 5 | 20 | ||

| 75W | 0.3Ω~30KΩ | 28 | 90 | 100 | 26 | 65 | 9 | 4 | 6 | 27 | ||

| 100W | 0.5Ω~30KΩ | 20 | 165 | 195 | 26 | 52 | 6 | 3 | 5 | 20 | ||

| 0.5Ω~30KΩ | 28 | 170 | 200 | 30 | 65 | 9 | 4 | 6 | 27 | |||

| 0.5Ω~30KΩ | 40 | 90 | 122 | 46 | 90 | 10 | 5 | 6 | 40 | |||

| 150W | 0.5Ω~30KΩ | 28 | 215 | 241 | 30 | 65 | 9 | 4 | 6 | 27 | ||

| 200W | 0.5Ω~30KΩ | 28 | 267 | 290 | 30 | 65 | 9 | 4 | 6 | 27 | ||

| 0.5Ω~30KΩ | 40 | 160 | 192 | 46 | 90 | 10 | 5 | 6 | 39 | |||

| 250W | 0.5Ω~30KΩ | 40 | 180 | 212 | 46 | 90 | 10 | 5 | 6 | 39 | ||

| 0.5Ω~30KΩ | 40 | 200 | 235 | 46 | 90 | 10 | 5 | 6 | 39 | |||

| 300W | 0.5Ω~30KΩ | 40 | 267 | 300 | 46 | 90 | 10 | 5 | 6 | 39 | ||

| 350W | 0.5Ω~30KΩ | 40 | 330 | 360 | 46 | 90 | 10 | 5 | 6 | 39 | ||

| 400w | 0.5Ω~10KΩ | 40 | 330 | 360 | 46 | 90 | 10 | 5 | 6 | 39 | ||

| 500W | 0.5Ω~10KΩ | 50 | 300 | 338 | 45 | 90 | 10 | 5 | 6 | 49 | ||

| 750W | 0.5Ω~10KΩ | 50 | 330 | 368 | 45 | 90 | 10 | 5 | 6 | 49 | ||

| 1000W | 0.5Ω~10KΩ | 60 | 250 | 305 | 64 | 130 | 15 | 5 | 6 | 59 | ||

| 0.5Ω~10KΩ | 60 | 430 | 485 | 64 | 130 | 15 | 5 | 6 | 59 | |||

| 1500W | 0.5Ω~10KΩ | 70 | 300 | 360 | 76 | 145 | 15 | 5 | 8 | 69 | ||

| 2000W | 0.5Ω~8KΩ | 70 | 430 | 490 | 76 | 145 | 15 | 5 | 8 | 69 | ||

| 3000W | 0.5Ω~5KΩ | 80 | 250 | 350 | 90 | 155 | 15 | 5 | 8 | 69 | ||

| 5000W | 0.5Ω~5KΩ | 80 | 430 | 530 | 90 | 155 | 15 | 5 | 8 | 80 | ||

| 10KW | 0.5Ω~5KΩ | 100 | 430 | 600 | 130 | 365 | 30 | 8 | 10 | 100 | ||

Comments